La línea de reciclaje de aluminio con rotura térmica es una línea de producción integral centrada en trituración, separación magnética y separación por corrientes de Foucault. Se usa principalmente para separar perfiles de aluminio, tiras de aislamiento térmico de nylon y impurezas ferrosas de puertas y ventanas de aluminio con rotura de puente térmico desechadas y rotas.

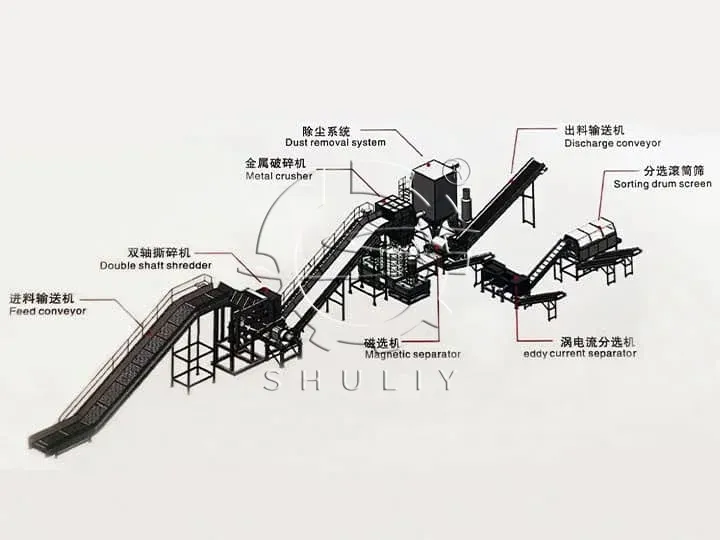

La línea de producción consta de transportador, trituradora de doble eje, trituradora de metal, separador magnético, separador por corrientes de Foucault y sistema de eliminación de polvo. Su capacidad de procesamiento es de 4t/h, y también podemos personalizar la línea de reciclaje según el volumen de producción objetivo del cliente.

Ventajas de la línea de reciclaje de marcos de ventanas de aleación de aluminio de chatarra

- Alta pureza en reciclaje de aluminio: Nuestra línea de producción utiliza procesos de trituración en múltiples etapas, separación magnética y separación por corrientes de Foucault para separar eficazmente el aluminio de los perfiles de aluminio con rotura térmica. El material de aluminio recuperado tiene bajas impurezas y alta pureza.

- Alto grado de automatización: Toda la línea de reciclaje de aluminio con rotura térmica funciona de manera continua y automática, requiriendo prácticamente ninguna operación manual desde la alimentación hasta la descarga.

- Amplio rango de aplicaciones: Ya sea marcos de ventanas y puertas de aluminio con rotura térmica completos, o recortes y restos desmontados, todos pueden ser procesados directamente por la línea de producción.

- Configuración de capacidad flexible: Nuestra línea de reciclaje de marcos de ventanas de aleación de aluminio con chatarra presenta un diseño modular, permitiendo una configuración flexible del equipo adaptada a los requisitos de volumen de procesamiento.

- Operación estable: Los equipos en la línea de reciclaje de perfiles de aluminio con rotura térmica de Shuliy utilizan materiales resistentes al desgaste, asegurando una larga vida útil y aptitud para operación continua a largo plazo.

Pasos en el reciclaje de perfiles de aluminio rotos

La línea de reciclaje de perfiles de aluminio rotos utiliza trituración en múltiples etapas y múltiples procesos de clasificación para lograr una separación eficiente de los materiales de aluminio. Los pasos principales de procesamiento son los siguientes:

Primaria→ trituración profunda→ eliminación de hierro→ separación de aluminio y no metales

Línea de reciclaje de aluminio con rotura térmica

Máquina trituradora de doble eje

La función de la trituradora de doble eje es para la trituración primaria, desgarrando grandes piezas de puertas y ventanas de aluminio rotas en materiales más pequeños, preparándolos para una trituración profunda y clasificación posteriores. Sus parámetros se muestran a continuación:

| Modelo | SL-1200 |

| Especificación de la herramienta | 450*40, 500*50 |

| Fuerza | 45*2/75*2 |

| Número de herramientas | 27/23 |

| Capacidad | 3000-5000kg/h |

Máquina trituradora de metal

La máquina trituradora de metal realiza trituración profunda del material triturado, y el tamaño de las partículas de aluminio triturado puede controlarse en 3-10 cm, facilitando la clasificación posterior.

| Modelo | SL-1600 |

| Fuerza | 110*2kw |

| Velocidad de rotación | 750 r/min |

| Capacidad | 4000-8000kg/h |

| Tamaño | 4400*2500*4200mm |

Separador magnético

El separador magnético se usa para eliminar impurezas ferrosas como tornillos, bisagras y clavos. No solo mejora la pureza de los materiales de aluminio, sino que también protege a los separadores de corrientes de Foucault del desgaste causado por objetos ferrosos duros.

Máquina separadora de corriente de Foucault

El separador de corrientes de Foucault es el equipo principal de la línea de reciclaje de aluminio con rotura térmica. Utiliza el principio de corrientes de Foucault para separar eficientemente metales no ferrosos como aluminio de materiales no metálicos como nylon y plásticos, logrando una recuperación de aluminio de alta pureza.

| Modelo | SL-1000 |

| Velocidad de rotación | 0-3000r/min |

| Ancho de banda | 1050mm |

| Capacidad | 10-12t/h |

| Fuerza | 7.5 1.5kw |

| Peso | 2200kg |

| Dimensión | 2980*1883*1210mm |

Sistema de eliminación de polvo

Su función es recoger polvo generado durante el proceso de clasificación, manteniendo el aire del taller limpio. Un sistema de eliminación de polvo estable y eficiente también garantiza la seguridad de los trabajadores y mejora la fiabilidad a largo plazo de la línea de producción.

Aplicación de la línea de reciclaje de aluminio con rotura térmica

Materiales procesables:

- Puertas y ventanas de aluminio con rotura de puente térmico rotas

- Perfiles de aluminio con rotura de puente térmico

- Residuos de desmontaje de puertas y ventanas

- Chatarra de aluminio con rotura de puente térmico

- Perfiles de aluminio que contienen tiras de aislamiento térmico de nylon

- Residuos de aluminio de construcción con rotura de puente térmico

Industrias de aplicación:

- Industria de reciclaje de recursos renovables

- Industria de clasificación de metales

- Industria de reciclaje de residuos de construcción

- Industria de reciclaje y desmontaje de puertas y ventanas

- Industria de reutilización de recursos ambientales

¿Cómo elegir el equipo de reciclaje de aluminio con rotura térmica?

- Selecciona el equipo del modelo adecuado según la capacidad de procesamiento diaria planificada para evitar capacidad insuficiente o equipo sobredimensionado, lo que puede conducir a inversiones desperdiciadas.

- Preste atención a la configuración del proceso de clasificación; un flujo de proceso razonable debe incluir trituración, eliminación de hierro y clasificación de metales no ferrosos.

- Priorizar la estabilidad y durabilidad del equipo, elegir equipos con estructura robusta y buena resistencia al desgaste para garantizar operación a largo plazo.

- Selecciona un diseño adecuado para la línea de reciclaje de aluminio con rotura térmica según el área de la fábrica, el flujo de material y el entorno de instalación para garantizar un funcionamiento fluido y un mantenimiento conveniente.

Preguntas frecuentes sobre la línea de reciclaje de perfiles de aluminio con chatarra

¿Qué materiales se reciclan principalmente en la línea de reciclaje de aluminio con rotura térmica?

Puertas y ventanas de aleación de aluminio con chatarra, perfiles de aluminio rotos, residuos de desmontaje de puertas y ventanas, y residuos de aluminio de construcción.

¿Es necesario desmontar manualmente el aluminio con rotura térmica?

No, todo el marco de aluminio puede ser alimentado directamente a la línea de producción para trituración y clasificación.

¿Se puede usar directamente el aluminio reciclado?

El material de aluminio recuperado tiene alta pureza y puede venderse directamente como materia prima de aluminio reciclado.

¿Cuál es la capacidad de producción de la línea de perfiles de aluminio con rotura térmica?

El modelo más vendido tiene una capacidad de 4 toneladas por hora, y podemos personalizarlo según los requisitos del cliente.

¿Proporcionan instrucciones de instalación?

Ofrecemos orientación de instalación remota o en sitio (se aplicarán gastos de viaje y alojamiento).