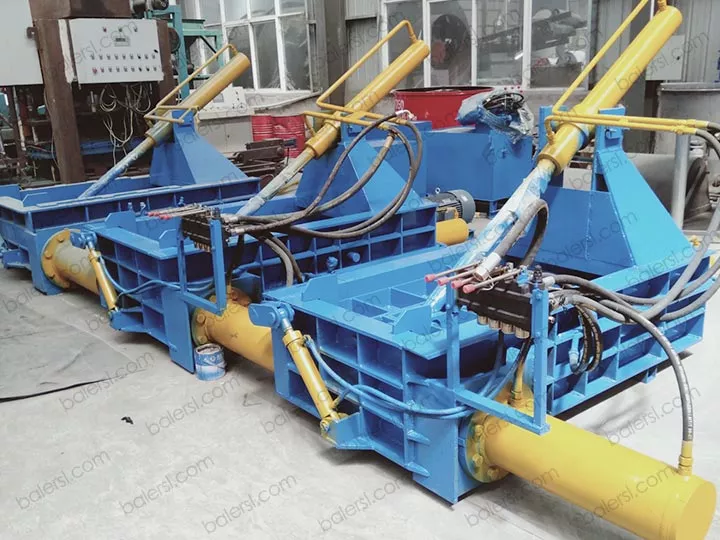

水平スクラップ金属圧縮機(水平スクラップメタルコンパクター)は、油圧金属圧縮機(hydraulic metal baler)、金属ブリケット機(metal briquetting machine)とも呼ばれます。この装置は、油圧による圧力で様々なスクラップ金属材料を様々な形状に押し出すことができます。押し出された材料は、輸送や再加工が非常に容易になります。また、スクラップが占めるスペースも削減します。Shuli社では、様々なモデルの水平油圧圧縮機を製造しており、ユーザーが様々な金属スクラップを効率的に処理するのに役立ちます。

横型スクラップコンパクターで扱える材料は何ですか?

水平スクラップ金属コンパクターは、さまざまな金属スクラップ、缶、ペイントバレル、鉄の削りくず、鋼スクラップ、アルミニウムスクラップ、銅スクラップ、ステンレス鋼スクラップ、カラー鋼タイルスクラップ、棒鋼、鉄線などをさまざまな形状に押し出すことができます。正方形、長方形、八角形、円筒形など。

輸送や溶解の供給に便利であり、お客様のニーズに応じてさまざまな形状やサイズの金属ベーラーをカスタマイズできます。

油圧板金ベーラー適用産業

水平スクラップ金属コンパクターは、金属リサイクル業界、金属加工業界、金属製品製造業界、スクラップリサイクルステーション、製鉄所、非鉄金属精錬業界などで広く使用されています。

工業用横型スクラップベーラーの特徴は何ですか?

- 高効率: 水平スクラップ金属圧縮機は油圧システムによって駆動され、高速で梱包する能力があり、効果的に効率を向上させることができます。

- 強力な圧縮力: 工業用スクラップ金属ベーラーは圧縮力が大きく、金属スクラップを高密度で梱包できるため、設置面積と輸送コストを削減できます。

- 安定性と信頼性: 油圧板金ベーラーは堅牢な構造設計と高品質の部品を採用しており、安定した信頼性の高い性能を持ち、長期間連続して動作できます。

- 操作が簡単: 横型金属ベーラーには、操作が簡単な制御システムが装備されており、操作がシンプルで便利で、オペレーターの技術的要件が軽減されます。

- 安全性: 水平スクラップ金属ベーラーは、オペレーターの安全を確保し、事故を回避するために安全保護装置を採用しています。