单轴撕碎机旨在轻松处理轻质材料,特别适合撕碎城市固体废物、塑料废物、橡胶、木材废物、纸张废物和工业大件废物。它通过单轴的旋转运动将金属废料撕碎、破碎,实现废料的再利用和资源回收。坚固的结构使机器能够承受高强度的使用。

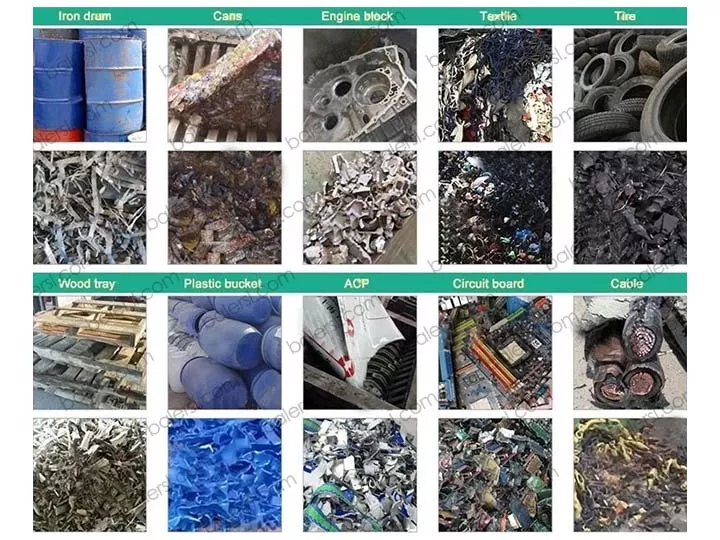

塑料橡胶撕碎机加工的物料

单轴撕碎机可满足各行业的废物回收要求,适用于塑料、纸张、木材、纤维、橡胶、生活垃圾回收处理等。

可回收材料范围广,适合回收各种大型固体材料、难处理材料、塑料容器和塑料桶、塑料垫材等。根据不同需要,出料粒度可小至20mm。

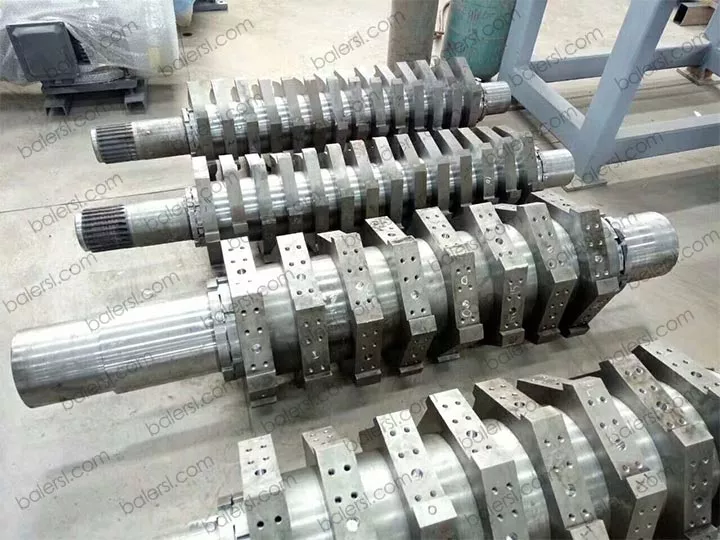

废金属撕碎机结构

单轴金属撕碎机结构简单、坚固。它由刀轴、定刀、载荷传递箱、箱体支撑、进给系统、液压推送系统、动力系统、电气控制系统等组成。废金属撕碎机主要用于撕碎木材、橡胶、塑料、纸张等废料。

单轴撕碎机工作原理

单轴金属撕碎机的工作流程包括进料、撕碎、分离和收集。

金属废料通过进料口进入机器,通过刀片的旋转而撕碎,然后通过筛网分离出不同尺寸的碎片,最后收集和提取有价值的金属材料。

首先,物料通过进料系统进入撕碎箱,箱内承载着撕碎刀片。

然后,推箱在液压缸的推动下将物料推向旋转刀辊,旋转的动刀和定刀将物料压碎。

第三,破碎后的物料从筛网落下。

最后,破碎后的物料通过辅助输送设备输送至下一道工序或收集包装。

单身和单身的区别 双轴金属撕碎机

单轴金属撕碎机和双轴金属撕碎机的主要区别在于结构和工作原理。

- 单轴撕碎机结构简单,占用空间小,适合金属废料的初步撕碎。

- 而双轴撕碎机结构复杂,具有较高的剪切和破碎能力,适合较大、较硬的金属废料的深加工。

单轴撕碎机详细技术资料

| 模型 | 800 |

| 功率(千瓦) | 30 |

| 推力(千瓦) | 2.2 |

出售金属撕碎机的特点

- 单轴撕碎机工具的使用和维护成本较低,相同功率与两轴撕碎机相比单轴撕碎机价格相对较低,更换工具方便。

- 硬齿面减速机,运转平稳,噪音低,扭矩大。

- 动刀采用冷作模具钢制成,具有良好的强度高韧性,切削性能高。

- 筛网更换方便,推箱导杆、导块可更换调整,速度平稳可调,推进力大而均匀。

- 外置轴承设计,可根据筛网孔径大小调节出料大小,防水防尘,延长轴承使用寿命。

单轴金属撕碎机易损件

在单轴金属破碎机中,刀片是重要的易损件。长时间使用后,刀片可能磨损或损坏,影响破碎效果。因此,定期检查和更换刀片是保持机器性能稳定的关键措施。

为什么选择蜀力的单轴破碎机?

作为专业金属废料处理设备的领先品牌,我们的单轴金属破碎机具有出色的性能和可靠的质量。我们致力于提供定制化解决方案,以满足客户的金属废料处理需求,提供适用的型号和配置,满足不同需求。

本厂生产的破碎机已出口到 德国、美国、法国、意大利、英国、加拿大、澳大利亚、巴西、印度、西班牙、墨西哥和俄罗斯。如果您对本设备感兴趣,请浏览本网站并随时与我们联系以获取更多详情和机器报价。