热断铝回收线是一条以破碎、磁选和涡流分选为核心的综合生产线,主要用于从废旧、破碎的桥梁铝门窗中分离铝型材、尼龙隔热条和铁磁杂质。

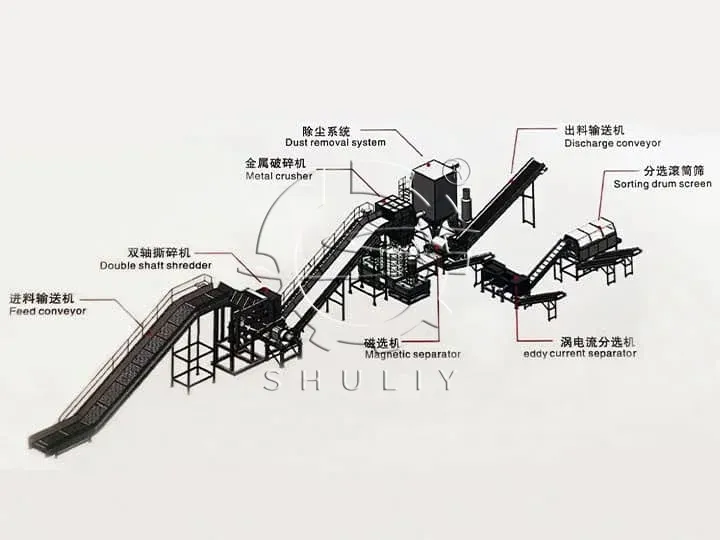

生产线由输送机、双轴破碎机、金属破碎机、非磁性分离器、涡流分选机和除尘系统组成。其处理能力为4吨/小时,也可以根据客户的目标产量定制回收线。

废铝合金门窗框回收线的优势

- 高铝回收纯度:我们的生产线采用多级破碎、磁选和涡流分选工艺,有效分离铝与热断铝型材。回收的铝料杂质少、纯度高。

- 高度自动化:整个热断铝回收线连续自动运行,几乎无需人工操作,从投料到出料全部自动完成。

- 广泛的应用范围:无论是完整的热断铝门窗框,还是切割废料和拆解残余,都可以直接由生产线进行处理。

- 灵活的产能配置:我们的废铝合金门窗框回收线采用模块化设计,便于根据处理量需求灵活配置设备。

- 运行稳定:舒利热断铝型材回收线设备采用耐磨材料,确保使用寿命长,适合长期连续运行。

回收破碎铝型材的步骤

破碎铝型材回收线采用多级破碎和多重分拣工艺,有效实现铝材料的分离,主要工艺步骤如下:

初级破碎→深度破碎→除铁→铝与非金属的分离

热断铝回收线的核心设备

双轴破碎机

双轴破碎机的功能是用于初级破碎,将大型破碎铝门窗撕裂成较小的物料,为后续深度破碎和分拣做准备。其参数如下:

| 模型 | SL-1200 |

| 工具规格 | 450*40, 500*50 |

| 力量 | 45*2/75*2 |

| 工具数量 | 27/23 |

| 容量 | 3000-5000kg/h |

金属破碎机

金属破碎机对破碎物料进行深度破碎,破碎铝粒大小可控在3-10厘米,便于后续分拣。

| 模型 | SL-1600 |

| 力量 | 110*2kw |

| 转速 | 750r/min |

| 容量 | 4000-8000kg/h |

| 尺寸 | 4400*2500*4200mm |

磁选机

磁选器用于去除铁磁杂质,如螺丝、铰链和钉子,不仅提高铝料的纯度,还保护涡流分选器免受硬铁杂质的磨损。

涡流分离机

涡流分选器是热断铝回收线的核心设备,利用涡流原理高效分离非铁金属,如铝,从非金属材料如尼龙和塑料中回收高纯度铝。

| 模型 | SL-1000 |

| 转速 | 0-3000r/min |

| 带宽 | 1050mm |

| 容量 | 10-12t/h |

| 力量 | 7.5 1.5kw |

| 重量 | 2200kg |

| 方面 | 2980*1883*1210mm |

除尘系统

其功能是收集在分拣过程中产生的粉尘,保持车间空气清新。稳定高效的除尘系统还能保障工人安全,提高生产线的长期可靠性。

热断铝回收线的应用

可加工的材料:

- 废旧断桥铝门窗

- 断桥铝型材

- 门窗拆解残余物

- 断桥铝废料

- 含有尼龙隔热条的铝型材

- 建筑用铝合金废料

应用行业:

- 可再生资源回收行业

- 金属分拣行业

- 建筑废料回收行业

- 门窗拆解与回收行业

- 资源再生利用行业

如何选择热断铝回收设备?

- 根据计划的日处理能力选择合适型号的设备,避免容量不足或设备过度配置,从而导致投资浪费。

- 注意分拣流程的配置,合理的工艺流程应包括破碎、除铁和有色金属分拣阶段。

- 优先考虑设备的稳定性和耐用性,选择结构坚固、耐磨性好的设备,确保长期运行。

- 根据厂区面积、物料流向和安装环境选择合适的热断铝回收线布局,确保运行顺畅,维护方便。

废铝合金门窗框回收线的常见问题

热断铝回收线主要回收哪些材料?

废铝合金门窗、破碎铝型材、门窗拆解残余物和建筑铝合金废料。

需要手动拆解热断铝吗?

不,整个铝框架可以直接投入生产线进行破碎和分拣。

回收的铝可以直接使用吗?

回收的铝材料纯度高,可直接作为再生铝原料销售。

热断铝型材生产线的产能是多少?

畅销型号的产能为每小时4吨,可根据客户需求定制。

你们提供安装说明吗?

我们提供远程安装指导或现场指导(差旅和住宿费用另算)。