金属スクラップシャーリングマシンは、さまざまな形状の冷間鋼や金属スクラップを切断するために使用できます。小型・軽量でせん断断面が大きいシアーです。したがって、さまざまなリサイクル企業、スクラップ鉄鋼工場、製錬および鋳造企業で広く使用されています。この装置は設置と操作が簡単で、ユーザーは時間を大幅に節約できます。

金属スクラップシャーリングマシンの簡単な紹介

シュリイが製造するさまざまなモデルの金属スクラップ剪断機があります。カッターの長さと作業時に生成される圧力はモデルによって異なります。お客様の具体的な状況に応じて適切なタイプの剪断機をお勧めします。

これまでに、当社の油圧シートメタルシャーは、フィリピン、マルタ、マレーシア、ガボン、アルジェリア、タンザニア、インドネシアなど、多くの国に販売されています。Shuliyは皆様との協力を楽しみにしています!

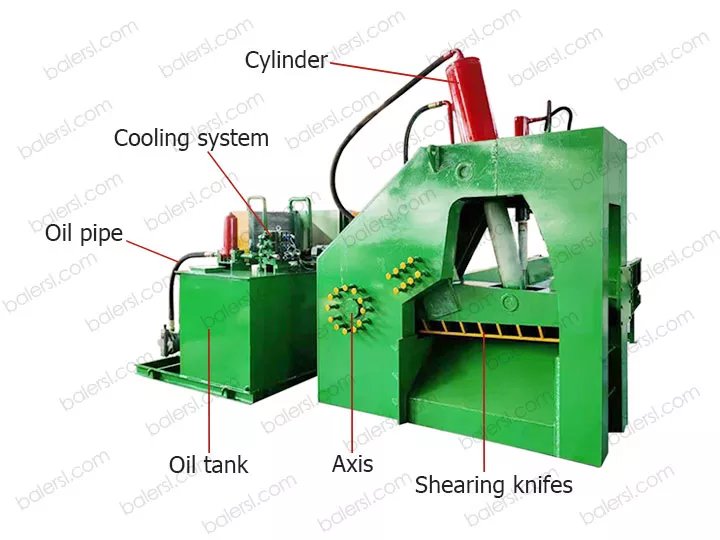

油圧板金シャーの構造

油圧板金剪断機は通常、手術台、シリンダー、パイプ、タンク、スピンドル、剪断ナイフなどの部品で構成されています。

- メインフレーム: この部分は、サポートと安定性を提供し、他のコンポーネントの取り付けを提供します。

- シャーリングエッジ: 金属材料の切断に使用される刃物に高強度素材を使用しています。

- 電源システム: 電気モーター、油圧システムなどを備え、強力なパワーとせん断圧力を提供します。

- 制御システム: タイガーヘッドシアーの動作制御やパラメータ調整に使用するシステムです。

廃金属シャーリング機の使用範囲

油圧せん断機の使用は、一定の長さをせん断し、頭部を切断し、尾部を切断し、エッジを切断し、試験片を切断し、圧延部品の局所的な欠陥を除去するために使用されます。

使用分野:

- 金属加工業: 金属板、金属パイプ、金属異形材などを切断し、さまざまな加工ニーズに対応するスクラップメタルシャーリングマシンです。

- スクラップリサイクル業: あらゆる種類の金属スクラップのせん断に使用できます。

- 自動車製造業: シート切断機は自動車部品や廃車などを切断し、廃棄物処理とリサイクルを実現します。

- 鉄道と橋の建設: 鉄道・橋梁建設における金属加工ニーズに応じて、レールや棒鋼などを切断することができる機械です。

油圧シャーリングマシンの詳細情報

| モデル | 300T |

| 装置圧力 | 2500KN |

| システム圧力 | 25MPA |

| 刃のサイズ | 1000mm |

| モーター出力 | 22KW |

| メールボックスの容量 | 360L |

| 切断時間 | 4~8回(調整可能) |

| 装置寸法 | 200012002100 |

油圧シート断裁機のワークフロー

油圧シート切断機の動作原理:

- パラメータを調整します。 金属材料の厚みや硬さに応じて、シャーブレードの位置やせん断圧力を調整してください。

- 金属材料を配置します。 せん断される金属材料は、スクラップ金属せん断機のテーブル上に置かれます。

- 機器を起動します。 制御システムを通じてタイガーヘッドシアーの動力システムを起動します。

- せん断金属材料: 高速かつ高圧で金属材料を切断するシャーブレードにより、高速かつ正確なせん断効果が得られます。

スクラップ金属切断機はどのように動作するのですか?

金属ハサミの利点

- ワニ鋏はプレートチェーンサイロを採用し、スムーズな供給を実現します。これにより、従来の供給機構による材料の押出時のランブル問題を回避できます。

- スクラップメタルシャーリングマシンのシャーリングシリンダーはボールヒンジで接続されており、シリンダーの安定性と寿命が向上します。これにより、フロントプレートガイド装置、低騒音、安定性、信頼性も向上します。

- 油圧駆動なので操作が簡単、メンテナンスも簡単です。取り付けが簡単で、タイガーヘッドハサミの取り付けに足ネジは必要ありません。

このシャーリングマシンにはどのような機器を組み合わせることができますか?

大容量シャーリングマシンは、効率と利便性を向上させるために、以下の補助装置と併用されることがよくあります。

- 搬送システム: スクラップメタルシャーリングマシンの作業エリアまで金属材料を搬送し、連続供給・排出するシステムです。

- スクラップ回収システム: この部品は、せん断加工で発生したスクラップを収集して処理し、その後リサイクルおよび廃棄するために使用されます。

タイガーヘッドシャーリングマシンとガントリーシャーリングの比較

- ガントリーシャー サイズが大きく、価格が高く、設置面積が大きいという特徴があります。動作原理の観点から、ガントリーシャーは一般に重スクラップ用に処理されます。重金属スクラップの処理が可能で、大規模な金属加工工場に適しています。

- タイガーヘッドシャーリングは、高圧、小型、加工範囲が広く、移動が容易であるという利点があります。したがって、タイガーヘッドハサミは一般的に中小型の金属スクラップを処理できます。