Uma grande enfardadeira de reciclagem de plástico é usada para comprimir garrafas plásticas usadas e outros itens. Ele ajuda a indústria de reciclagem a comprimir suavemente todos os tipos de resíduos leves com sua capacidade de processamento eficiente, economia de energia e recursos ecologicamente corretos.

Introdução à enfardadeira de reciclagem de plástico

Shuliy possui dois tipos de enfardadeiras para reciclagem de plástico, semiautomáticas e automáticas. Além disso, existem diferentes modelos de enfardadeiras, que possuem diferentes saídas para movimentação de materiais. As enfardadeiras automáticas para garrafas de plástico produzidas pela Shuliy têm boa rigidez e estabilidade, formato bonito e generoso, fácil operação e manutenção, segurança e economia de energia e baixo custo de investimento em projetos de fundação de equipamentos, etc. você!

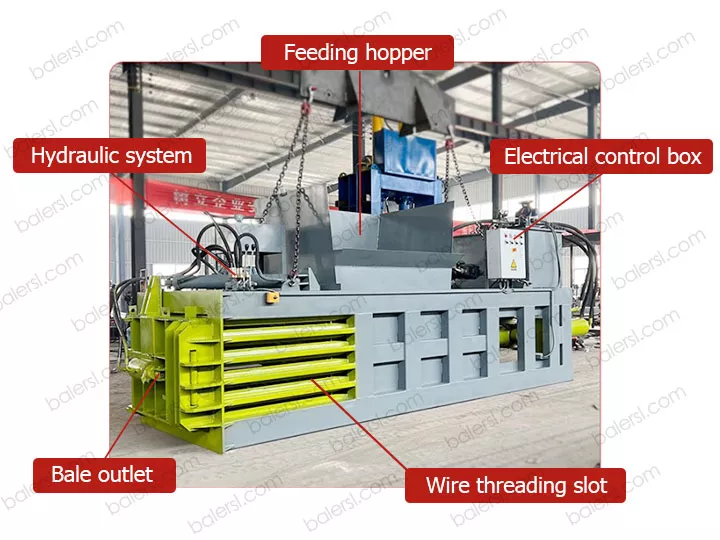

Composição de enfardadeiras de garrafas plásticas

A máquina automática de compactação de reciclagem de plástico pode ser operada por uma única pessoa através de controlo remoto, realizando uma operação totalmente automática de compactação de papel usado. A máquina inclui várias unidades, como estrutura de compactação, unidade principal, correia transportadora, máquina automática de passagem de fios e máquina automática de aparafusar.

Características de cada parte

- Estrutura da enfardadeira: A utilização de chapa de aço padrão nacional, combinada com a alta tecnologia do soldador principal, confere uma aparência duradoura.

- Correia transportadora: Usando estrutura de viga I espessada de alta qualidade, correia transportadora tipo placa de aço de alta resistência, durável e não deformada.

- Sistema hidráulico: Bomba variável de alta velocidade, vedação de óleo do cilindro hidráulico da válvula solenóide e outros acessórios importantes de alta qualidade, de modo que a pressão da enfardadeira, velocidade rápida e baixo ruído.

- Sistema de controle elétrico: Motor de núcleo de cobre puro, controlador de programação PLC original, longa vida útil.

Faixa de aplicação da enfardadeira de resíduos de plástico

Uma grande enfardadeira de reciclagem de plástico é usada principalmente para lidar com todos os tipos de resíduos de garrafas plásticas, incluindo garrafas de bebidas, frascos de xampu, frascos de detergente, latas, barris de plástico, jarros de plástico, sacos de tecido, sacos de plástico, etc. de plásticos como polietileno (PE) ou polipropileno (PP), que apresentam boa plasticidade e reciclabilidade.

É amplamente utilizado em todos os tipos de fábricas de resíduos de papel, empresas de reciclagem de materiais antigos e outras empresas unitárias, adequado para enfardamento e reciclagem de resíduos de papel antigos, canudos de plástico, etc. intensidade de trabalho, economizar mão de obra e reduzir custos de transporte.

Quais são os benefícios de usar enfardadeiras de garrafas plásticas?

- Capacidade de processamento eficiente: Grandes máquinas enfardadeiras para reciclagem de plástico podem compactar e embalar de forma rápida e eficaz um grande número de garrafas plásticas usadas, melhorar a eficiência e reduzir custos de mão de obra e tempo.

- Economia de energia e proteção ambiental: O processamento por compressão reduz o volume de resíduos de garrafas plásticas, diminuindo a ocupação de transporte e espaço de armazenamento. Isso ajuda a economizar energia e reduzir a poluição ambiental.

- Tratamento de acompanhamento oportuno: Garrafas plásticas comprimidas e embaladas são mais fáceis de armazenar, transportar e reciclar. Isso proporciona comodidade para processamento posterior e reduz a ocupação de aterros sanitários.

Parâmetros técnicos da grande enfardadeira para reciclagem de plástico

| Modelo | SL-120 |

| Pressão hidráulica kn | 1200 |

| Potência (kw) | 22+15 |

| Tamanho do fardo (mm) | 900*1100 |

| Padrão de tensão | 3ph 380v ou personalizado |

| Óleo hidráulico | marca de óleo hidráulico resistente |

| Capacidade | 8 fardos por hora, personalizados |

| Sistema de controle | PLC, totalmente automático, semiautomático |

Como funciona a enfardadeira de resíduos de plástico?

As garrafas plásticas soltas são comprimidas em blocos de embalagem compactos por meio de um poderoso sistema hidráulico. Seu princípio de funcionamento é simples e eficiente: depois que as garrafas plásticas são colocadas na câmara de compressão, o dispositivo hidráulico aplica uma enorme pressão para comprimi-las.

Características técnicas da enfardadeira de sacos plásticos

- Acionamento hidráulico totalmente automático, com opção de operação de controle manual ou automático por PLC.

- Diferentes formas de descarga do fardo: Descarga contínua do fardo, impulso hidráulico do fardo e outras formas diferentes com e sem porta são opcionais.

- Instalação sem parafuso de base, caso não haja alimentação o motor diesel pode ser instalado como potência.

- Articulação de estrutura esférica entre o cilindro de impulso e a cabeça de impulso, boa confiabilidade e longa vida útil da vedação de óleo.

- A enfardadeira de garrafas plásticas possui um cortador disperso na porta de enchimento, que corta o excesso e facilita o enfardamento.

- Projeto de circuito hidráulico de baixo ruído, alta eficiência e baixa falha.

Produzimos diferentes formas de prensas, incluindo prensas verticais que também podem ser usadas para embalar garrafas de plástico. Sinta-se à vontade para navegar neste site e entre em contato conosco para mais detalhes e cotações de máquinas.