Mit Schrottscheren können verschiedene Formen von Kaltstahl und Altmetall geschnitten werden. Diese Schere ist klein, leicht und hat einen großen Scherquerschnitt. Daher wird es häufig in verschiedenen Recyclingunternehmen, Schrottstahlwerken sowie Schmelz- und Gießereien eingesetzt. Das Gerät ist einfach zu installieren und zu bedienen und kann den Benutzern helfen, viel Zeit zu sparen.

Kurze Einführung in die Schrottschere

Es gibt verschiedene Modelle von Schrottmetall-Schneidemaschinen, die von Shuliy hergestellt werden. Die Länge des Schneidmessers und der beim Arbeiten erzeugte Druck sind bei den verschiedenen Modellen unterschiedlich. Wir empfehlen die passende Art von Schneidern entsprechend der spezifischen Situation des Kunden.

Bis heute wurden unsere hydraulischen Blechscheren in viele Länder verkauft. Zum Beispiel die Philippinen, Malta, Malaysia, Gabun, Algerien, Tansania, Indonesien usw. Shuliy freut sich auf die Zusammenarbeit mit Ihnen!

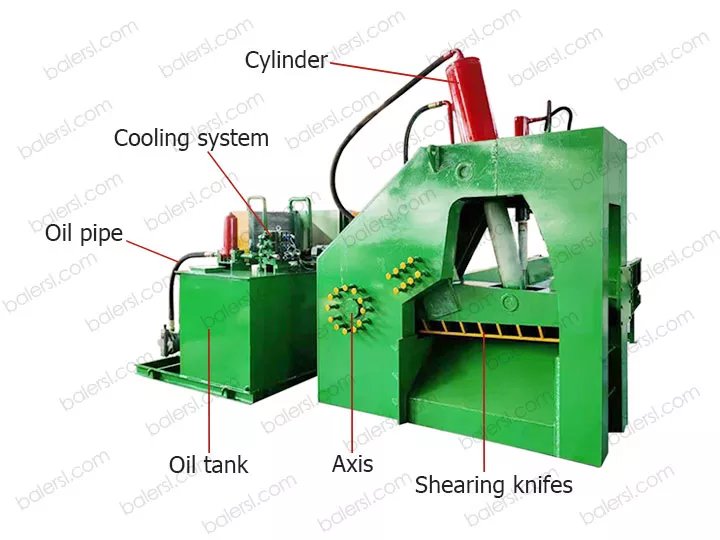

Aufbau einer hydraulischen Blechschere

Die hydraulische Blechschere besteht normalerweise aus folgenden Teilen: Enthält im Allgemeinen den Operationstisch, Zylinder, Rohr, Tank, Spindel, Schermesser usw.

- Der Hauptrahmen: Dieser Teil kann für Halt und Stabilität bei der Installation anderer Komponenten sorgen.

- Scherkante: Die Verwendung hochfester Materialien aus Klingen zum Schneiden von Metallmaterialien.

- Stromversorgungssystem: einschließlich Elektromotoren, Hydrauliksystemen usw., um starke Kraft und Scherdruck bereitzustellen.

- Steuerungssystem: Dieses System dient zur Steuerung des Betriebs der Tigerkopfschere und zur Parametereinstellung.

Verwendung des Umfangs der Altmetallschermaschine

Die Verwendung einer hydraulischen Schermaschine wird zum Scheren der festen Länge, zum Schneiden des Kopfes, zum Schneiden des Schwanzes, zum Schneiden der Kante, zum Schneiden der Probe und zum Entfernen lokaler Defekte der gewalzten Teile verwendet.

Einsatzgebiete:

- Metallverarbeitende Industrie: Schrottschere zum Scheren von Metallplatten, Metallrohren, Metallprofilen usw., um eine Vielzahl von Verarbeitungsanforderungen zu erfüllen.

- Schrottrecyclingindustrie: Es kann zum Scheren aller Arten von Altmetall verwendet werden.

- Automobilindustrie: Blechschneidemaschinen können Autoteile, verlassene Fahrzeuge usw. abschneiden, um Abfallentsorgung und Recycling zu erreichen.

- Eisenbahn- und Brückenbau: Diese Maschine kann Schienen, Stahlstangen usw. für die Metallverarbeitung im Eisenbahn- und Brückenbau scheren.

Detaillierte Informationen zur hydraulischen Schermaschine

| Modell | 300T |

| Gerätedruck | 2500 kN |

| Systemdruck | 25MPA |

| Klingengröße | 1000mm |

| Motorleistung | 22KW |

| Postfachkapazität | 360L |

| Schnittzeiten | 4-8 mal (einstellbar) |

| Geräteabmessungen | 200012002100 |

Arbeitsablauf einer hydraulischen Blechschneidemaschine

Das Arbeitsprinzip der hydraulischen Blechschneidemaschine:

- Passen Sie die Parameter an: Passen Sie die Position des Schermessers und den Scherdruck entsprechend der Dicke und Härte des Metallmaterials an.

- Positionieren Sie das Metallmaterial: Das zu scherende Metallmaterial wird auf den Tisch der Schrottschere gelegt.

- Starten Sie das Gerät: Starten Sie über das Steuersystem das Antriebssystem der Tigerkopfschere.

- Schermetallmaterial: Schermesser mit hoher Geschwindigkeit und hohem Druck auf das zu scherende Metallmaterial, um einen schnellen und präzisen Schereffekt zu erzielen.

Wie funktionieren die Schrottschneidemaschinen?

Vorteile der Blechschere

- Alligatorscheren verwenden einen Plattenkettensilo, um eine reibungslose Beschickung zu erreichen. Dadurch kann der herkömmliche Zuführmechanismus zur Zuführung des Materialextrusionsgeräuschs vermieden werden.

- Der Scherzylinder der Schrottschermaschine ist durch ein Kugelscharnier verbunden, was die Stabilität und Lebensdauer des Zylinders verbessert. Dadurch erhöht sich auch die Frontplattenführung, die Geräuscharmut, die Stabilität und die Zuverlässigkeit.

- Mit hydraulischem Antrieb, einfache Bedienung, einfache Wartung. Einfach zu installieren, für die Installation der Tigerkopfschere ist keine Fußschraube erforderlich.

Welche Ausrüstung kann mit dieser Schermaschine kombiniert werden?

Schermaschinen mit hoher Kapazität werden häufig zusammen mit der folgenden unterstützenden Ausrüstung verwendet, um die Effizienz und den Komfort zu verbessern:

- Fördersystem: Dieses System wird verwendet, um Metallmaterialien zum Arbeitsbereich der Schrottschermaschinen zu transportieren und sorgt für eine kontinuierliche Zufuhr- und Entladefunktion.

- Schrottsammelsystem: Dieser Teil wird zum Sammeln und Verarbeiten des beim Scheren anfallenden Abfalls für die anschließende Wiederverwertung und Entsorgung verwendet.

Tigerkopfscheren im Vergleich zu Portalscheren

- Portalschere zeichnet sich durch große Größe, hohen Preis und große Stellfläche aus. Vom Funktionsprinzip her wird die Portalschere in der Regel für schwere Schrotte eingesetzt. Er kann Schwermetallschrott verarbeiten, geeignet für große Metallverarbeitungsbetriebe.

- Tigerkopf-Schermaschinen bieten die Vorteile eines hohen Drucks, einer geringen Größe, eines großen Verarbeitungsbereichs und einer einfachen Bewegung. Daher kann die Tigerkopfschere im Allgemeinen kleine und mittlere Metallschrotte verarbeiten.