High quality metal scrap baling machines are important equipment for handling scrap metal. Choosing a high quality horizontal metal baler can improve efficiency and guarantee the stability of the equipment. Here are some key points to help you pick a quality horizontal metal baler.

Observing the scrap metal recycling machine box

The quality of the metal scrap baling machine box directly affects the stability and durability of the equipment. Pay attention to the box body stress parts of the tendon density and material thickness. These places are the main force parts of the equipment, the selection of the right thickness of the steel plate can increase the load-bearing capacity of the equipment. According to the force of different parts, the use of different types and thicknesses of steel plate ensures the stability and durability of the scrap metal recycling equipment.

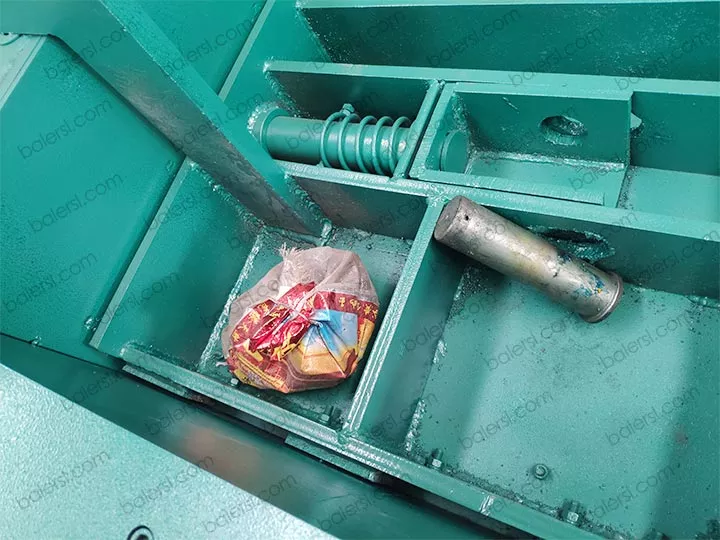

Pay attention to the quality of the metal recycling machine liner

High quality metal scrap baling machine box internal by a number of liner plates assembled. Liner plates as a protective layer of equipment, with high strength and hardness, can effectively reduce the wear and tear of scrap metal on the inside of the equipment, extending the service life of the metal baler. Ensure that the quality and installation of the liner plate are intact, which can effectively protect the performance and life of the equipment.

Concerned about the high quality metal scrap baling machine welding craft

The front end of the metal baler box steel plate stress part needs to be welded. The quality of the welding process is directly related to the stability and safety of the high quality metal scrap baling machine. The welding interface should be properly broken welding, the angle of the broken mouth is about 45 degrees. The welding should be flat and even, without false welding or bubbles. After the welding is completed, the welding slag must be cleaned up, leaving no residue.

Carefully observe the hydraulic cylinder

The hydraulic cylinder is an important part of the high quality metal scrap baling machine. When purchasing, you should pay attention to the material and color of the seal, and also carefully observe whether there are scratches or mechanical scars on the piston rod. The structure of a hydraulic cylinder includes a buffer device, oil outlet device, cylinder cover, piston, piston rod, sealing device, etc. Make sure the quality and integrity of these parts.

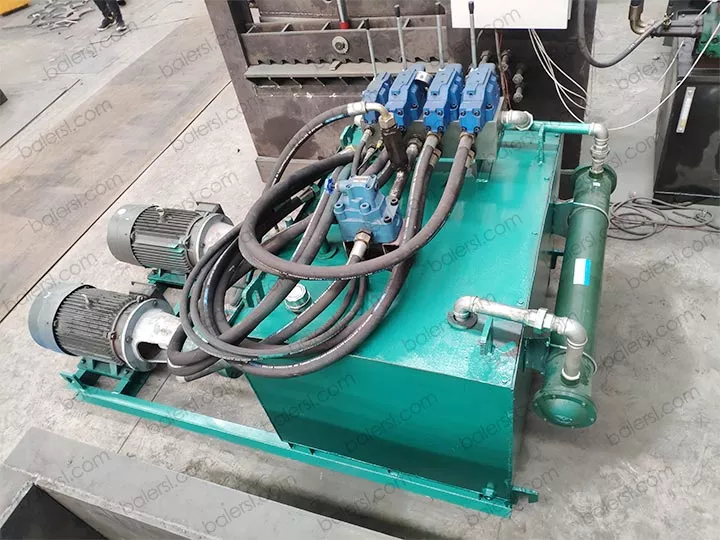

Check the key components of the scrap metal recycling machine’s hydraulic station

A hydraulic station is the power source of a high quality metal scrap baling machine, mainly composed of motor, oil pump, oil tank, cooling system, heating system, etc. When choosing a hydraulic station, pay attention to the noise of the equipment to ensure normal operation and no abnormal noise. Check whether the oil tank is cleaned and free of welding residue. At the same time, when the oil temperature exceeds 80℃, pay attention to the thermal expansion of hydraulic components to avoid leakage, jamming, and other abnormal operation.

We, Shuliy, produce various forms of balers, for example, vertical metal balers, and horizontal plastic balers. We use high quality materials and strictly supervise each production process to ensure that we provide our customers with high quality scrap metal recycling machines. Welcome to consult us anytime!