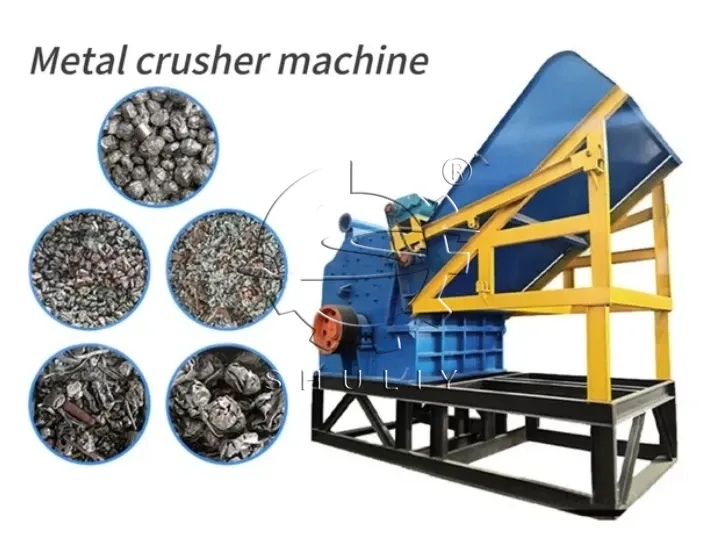

The metal crusher machine is an eco-friendly machine used to crush various types of waste metal, such as paint buckets, waste aluminum, and end-of-life vehicles. It can quickly break large, irregular metal materials into 3–10 cm metal balls or metal pieces.

As a professional supplier of recycling equipment, our metal shredder machine is durable and highly efficient, with processing speeds ranging from 600 to 18,000 kg/h. Please feel free to contact us for more information!

Excellent features of metal crushing machine

- Our metal shredder machine has a processing capacity of 600–18000 kg/h, adaptable to various production scales.

- The final material diameter is 3–10 mm, facilitating subsequent transportation and processing.

- The hammers and screen plates of the Shuliy metal crusher machine are made of alloy steel casting, ensuring a long service life and high crushing efficiency.

- The blade thickness and number of claws in this scrap aluminum shredder can be changed according to different materials, improving its applicability.

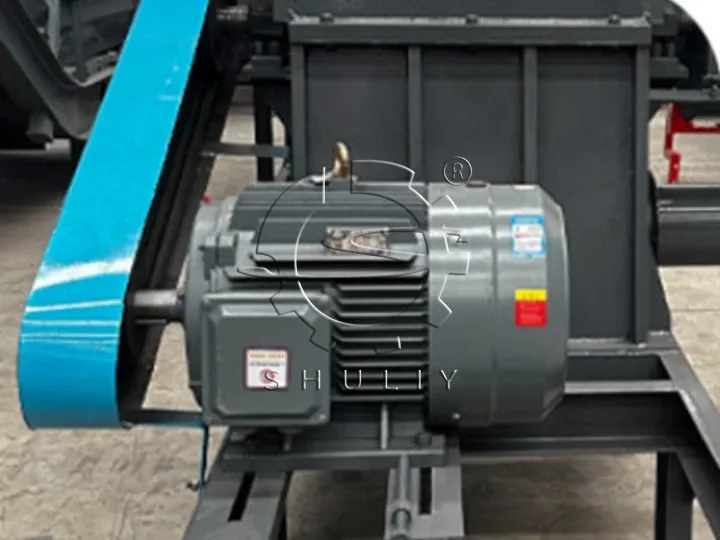

- The metal shredding machine is equipped with an all-copper core motor, offering low energy consumption and a long service life.

- Our waste aluminum shredder machine uses extra-thick steel plates, making it robust, durable, and highly safe.

- The feed inlet of this equipment features a sealed design, effectively preventing metal fragments from flying out.

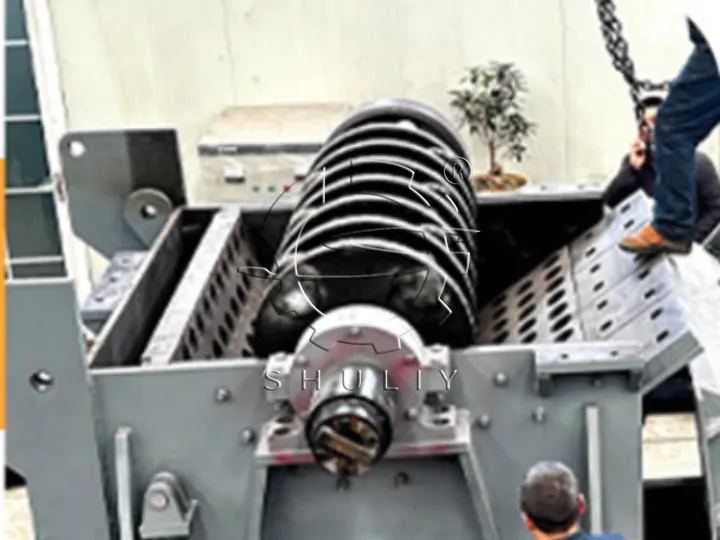

How do metal crusher machine work?

The metal crushing machine primarily relies on a high-speed rotating rotor to drive hammers, which powerfully impact, collide, and compress the scrap metal entering the crushing chamber, rapidly breaking it down and pulverizing it.

Within the chamber, the material continuously collides with the hammers and screen plate, gradually reducing the particle size. Once it reaches the size set by the screen plate, it is automatically discharged.

Structure of waste aluminum crushing machine

The metal crusher machine mainly consists of the following parts:

- Feeding port: Thickened sealing design to prevent material from flying out.

- Crushing chamber: Internally equipped with wear-resistant alloy hammers, blades, and screen plates.

- Heavy-duty rotor: High-strength design providing powerful crushing force.

- Cast steel bearings: High load-bearing capacity, ensuring stable operation.

- Copper motor: Energy-saving all-copper core motor, powerful and long-lasting.

- Machine body: Constructed from extra-thick welded steel plates, robust and durable.

- Safety system: Includes motor overload protection and power interlock system.

Application of aluminum shredder machine?

Shuliy metal crusher machine is suitable for use in scrap metal recycling stations, renewable resource processing plants, scrap metal treatment centers, and steel mill subsidiaries.

The metal crushing machine can efficiently process various metal scraps, such as aluminum alloy windows and doors, scrapped vehicles and dismantled parts, flattened car bodies, bicycles, appliance casings, various sheet metal, paint buckets, scrap steel bars, oil filters, and aluminum and iron cans.

Models and parameters of metal shredding machine

To meet the production needs of different customers, we offer a variety of models from small to large, with specific parameters as follows:

| Model | Power(kw) | Rotational speed(r/min) | Capacity(kg/h) | Size(mm) |

| BDL-600 | 18.5-22 | 860 | 600-800 | 2000*1200*1900 |

| BDL-800 | 30-37 | 860 | 800-1000 | 2200*1500*2200 |

| BDL-1000 | 55-75 | 860 | 2500-3500 | 2800*1800*3100 |

| BDL-1300 | 90-110 | 750 | 3500-5000 | 3500*2100*3800 |

| BDL-1600 | 110*2 | 750 | 4000-8000 | 4400*2500*4200 |

| BDL-1800 | 160*2 | 650 | 8000-12000 | 4700*2900*4500 |

| BDL-2000 | 220*2 | 650 | 10000-18000 | 5000*3200*4600 |

Factors affecting the price of metal shredder

The price of the metal crusher machine is influenced by several factors, including the equipment’s processing capacity, crushing chamber size, hammer and screen material, level of automation, and whether auxiliary systems such as magnetic separators and dust collection equipment are required.

Generally, the larger the processing capacity, the more wear-resistant the material, and the more complete the configuration, the higher the price. Furthermore, customization requirements will also affect the final quote.

How to choose aluminum crushing machine?

When selecting the metal crusher machine, pay attention to the following points:

- Choose the appropriate machine model based on output: Select a suitable output based on daily processing volume, production plan, and future expansion needs to avoid waste and maintain production efficiency.

- Pay attention to the materials of core components: Are the hammers, screen plates, and machine body made of alloy steel? Is the machine body thickened? These factors affect the wear resistance and lifespan of the equipment; the more wear-resistant, the more cost-effective.

- Choose a motor with better power performance: A high-power, all-copper-core motor is not only more energy-efficient but also more durable and less prone to overheating, ensuring long-term continuous operation.

- Emphasis on safety features: Features such as power interlocks and enclosed feed inlets improve equipment safety and prevent metal from flying out.

Contact us immdeitadely!

The metal crusher machine is key equipment for waste metal processing and recycling. Besides the metal crusher, we also provide supporting machines such as metal baler machine, metal shredder, and metal shear to create efficient recycling solutions for different materials and applications. Feel free to contact us for more details!